IPA Series Addressable Fire Alarm Systems

Potter's IPA fire systems use state-of-the-art addressable sensors and control modules which utilize the robust PAD protocol to provide you the flexibility needed to tackle demanding applications. From 60 to 4,064 addressable points, you can be sure that your IPA fire system is ready to tackle jobs of any size and scope. With industry leading IP technology, take advantage of Potter's multiple remote monitoring and control solutions as well as email notifications and reminders.

IPA-4000

IPA-4000

- 127 up to 4,064 Addresses

- 6 Programmable NACs

- 10A Power Supply

- 4 I/O Circuits

- Listed for both Water and Chemical (Agent) releasing

- UUKL Listed for Smoke Control

IPA-4000E

IPA-4000E

- Expandable design with optional PSK-1000B or SCUI-1000B for integrated programmable soft keys or smoke control zones

- 127 up to 4,064 Addresses

- 6 Programmable NACs

- 10A Power Supply

- 4 I/O Circuits

- Listed for both Water and Chemical (Agent) releasing

- UUKL Listed for Smoke Control

IPA-100

IPA-100

- 127 Addresses

- 2 Programmable NACs

- 5A Power Supply

- 2 I/O Circuits

- Listed for both Water and Chemical (Agent) releasing

- UUKL Listed for Smoke Control

Become a Potter ESD

Potter has several dealer programs designed to fit your organization's fire alarm systems and equipment needs. Our most advanced line of IPA fire alarm system are only available to direct dealers. Please contact us to inquire about becoming a Potter ESD for access to this product line.

Become a Potter ESD IPA Log InPeripheral Devices

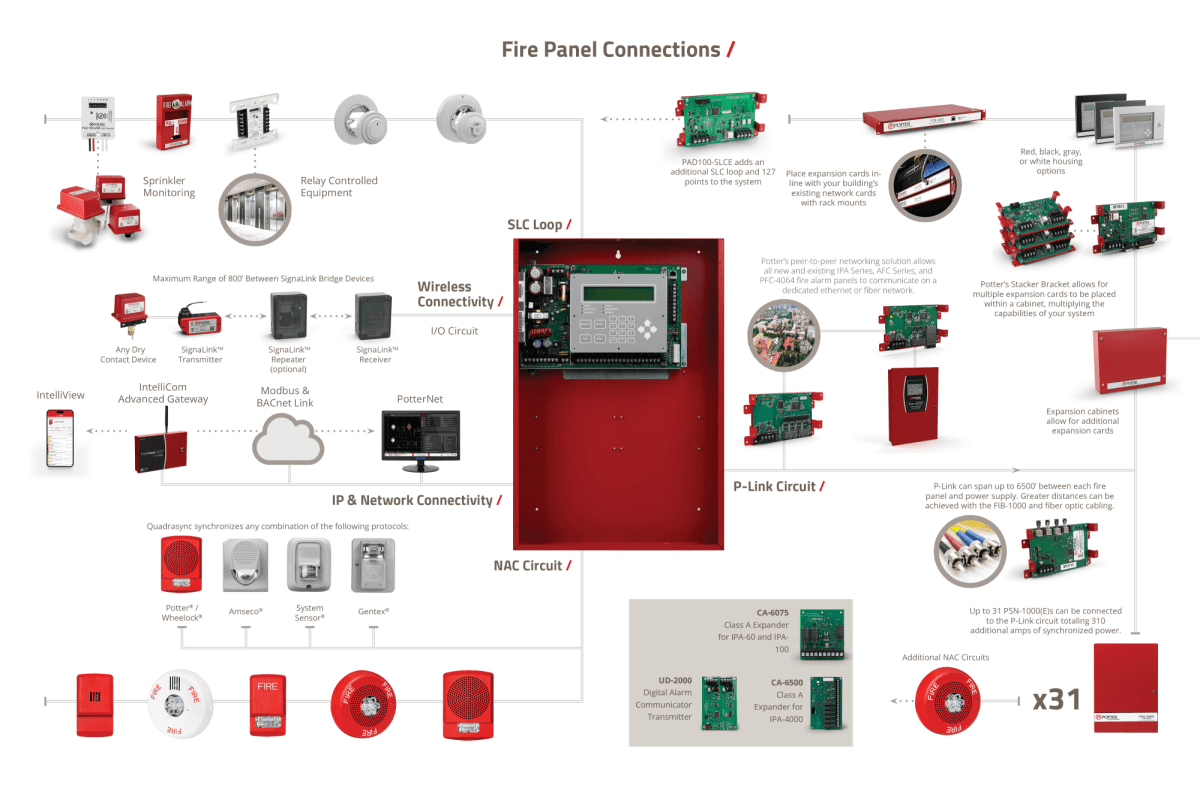

P-Link Circuit

The P-Link circuit is a 4-terminal connection that provides both power and data between fire alarm control panels, power expanders, and accessory devices in the field. Each P-Link connection is rated 1 amp at 24 volts and can span a maximum of 6500 feet between any P-Link device. The PSN-1000(E) power expander acts as a P-Link repeater and can provide additional power and distance. Greater distances can also be achieved with the FIB-1000 fiber interface module and fiber optic cabling.

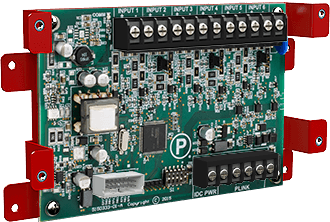

IDC-6

Initiating Device Circuit Expander

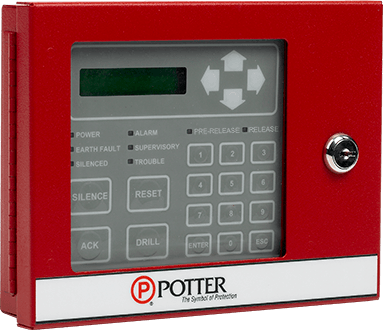

RA-6075R

LCD Releasing Annunciator

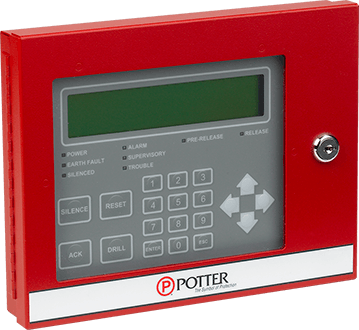

RA-6500R

LCD Releasing Annunciator

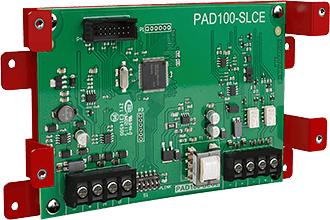

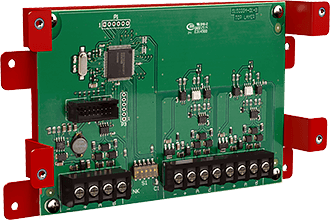

PAD100-SLCE

Addressable Loop Expander

LED-16

16 Zone LED Annunciator

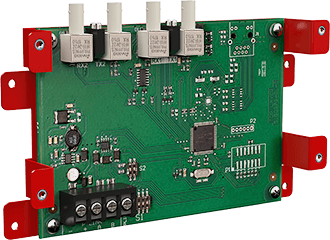

FCB-1000

Fire Communications Bridge

FIB-1000

Fiber Interface Bridge

DRV-50

LED Driver Module

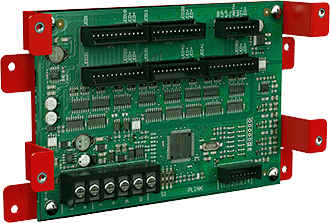

MC-1000

Multi-Connect Expander

RLY-5

Relay Expander

SPG-1000

Serial Parallel Gateway

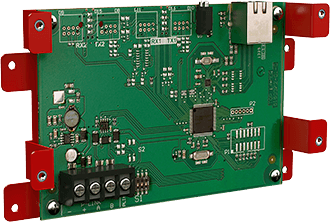

SLCE-127

SLC Loop Expander

PSK-1000

Programmable Soft Keys

SCUI-1000

Smoke Control User Interface

SLC Loop

Potter's addressable fire systems use state-of-the-art addressable sensors and control modules which utilize the robust PAD protocol to provide you the flexibility needed to tackle demanding applications. All of Potter's new addressable fire systems use the same devices to ensure a clear migration path as your systems grow in size and scope.

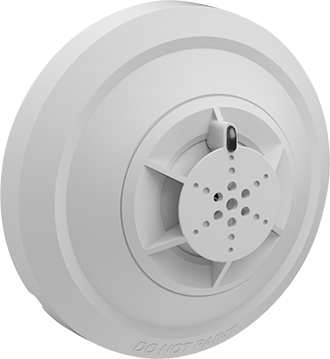

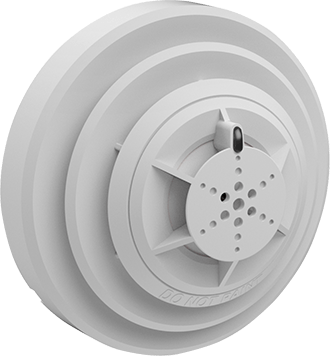

PAD300-PD

Photoelectric Smoke Detector

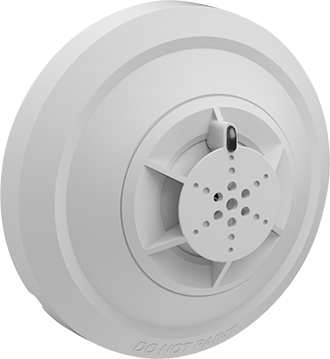

PAD300-HD

Heat Detector

PAD300-PHD

Photoelectric Smoke/Heat Detector

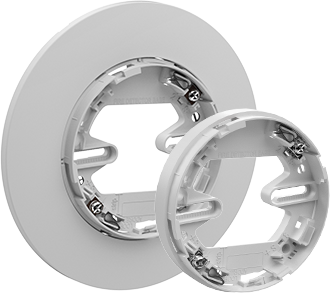

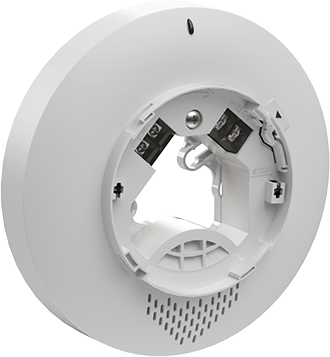

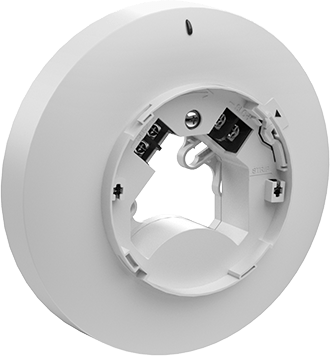

PAD300-4DB/6DB

4"/6" Detector Base

PAD300-SB

Addressable Sounder Base

PAD300-LFSB

Addressable Low Frequency Sounder Base

PAD300-DD

In-Duct Smoke Detector

PAD300-DUCT

Analog Addressable Duct Detector

PAD300-DUCTR

Analog Addressable Duct Detector

PAD300-CD

Carbon Monoxide Detector

PAD300-PCD

Photoelectric Smoke/CO Detector

PAD300-RB

Addressable Relay Base

PAD300-IB

Isolator Base

PAD300-IM

Isolator Module

PAD300-HD-I

Heat Detector With Isolation

PAD300-PCD-I

Photoelectric Smoke/CO Detector With Isolation

PAD300-PD-I

Photoelectric Smoke Detector with Isolation

PAD100-LED

Addressable LED Module

PAD100-DIM

Dual Input Module

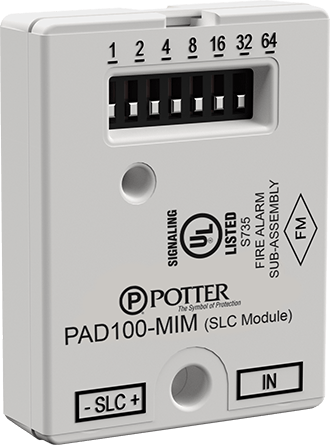

PAD100-MIM

Micro Input Module

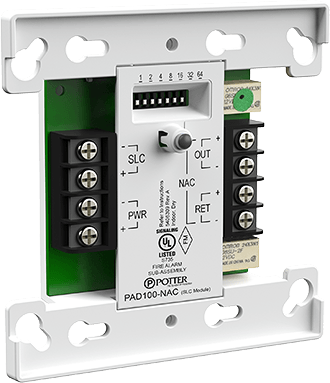

PAD100-NAC

Notification Appliance Circuit

PAD100-OROI

One Relay One Input Module

PAD100-RM

Relay Module

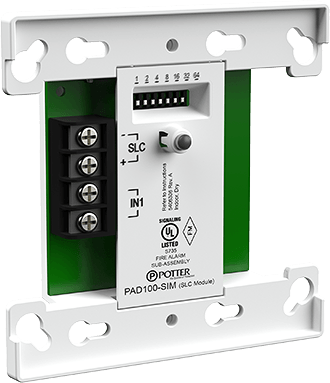

PAD100-SIM

Single Input Module

PAD100-SM

Speaker Module

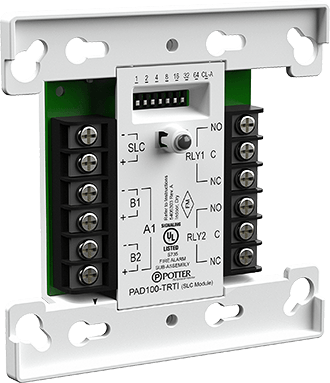

PAD100-TRTI

Two Relay Two Input Module

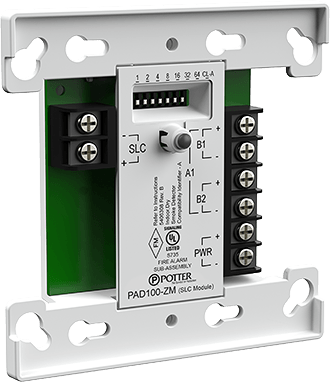

PAD100-ZM

Zone Module

PAD100-PSSA-PSDA

Addressable Pull Station Single/Dual Action

PAD100-SPKB

Speaker Base

PAD200-PCHD

Photoelectric Smoke / Heat / Carbon Monoxide Detector

PAD100-LEDK

Addressable LED with Key Switch

PAD100-DRTS

Duct Remote Test Switch

NAC Circuit

PE-HN/HS/ST

Horns and LED Strobes

PE-LFHN/LFHS

Low Frequency Sounders and Sounder Strobes

PE-SPK/SPST

Speakers and Speaker Strobes

Fire Panel Connections

Click the image below to view IPA fire panel connections.

Life Safety Software

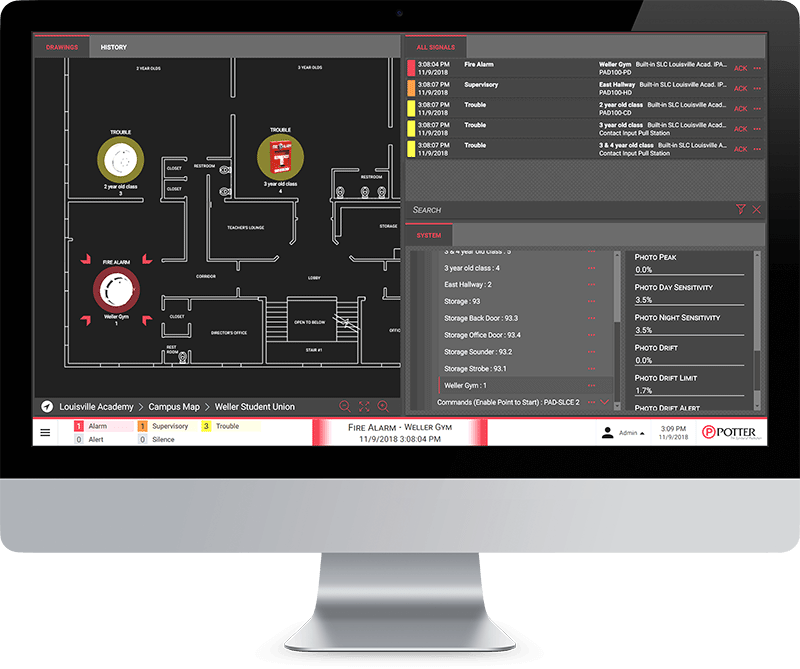

PotterNet Graphical Software

The PotterNet Fire and Facility Supervising Station is a desktop application that facilitates the monitoring and control of IPA, AFC/ARC, and PFC-4064 fire alarm control panels. It utilizes a distributed client-server model for communication in order to reduce or eliminate single points of failure.

Available in both UL and non-UL Listed versions, PotterNet will monitor all compatible panels in a single building, on a local campus, or across multiple sites worldwide. Configurations with as many as 1,000 panels and 15 graphical PotterNet stations can address your largest system needs.

Learn More

IntelliView™ Cloud Monitoring

Monitor your fire panel from anywhere in the world and take full advantage of the industry leading smart features of the Potter IntelliView dashboard. Simply connect to the building's networked internet connection and register your device. You will be able to remotely view the status of your Potter connected systems from your computer, tablet, or smartphone.

Learn More

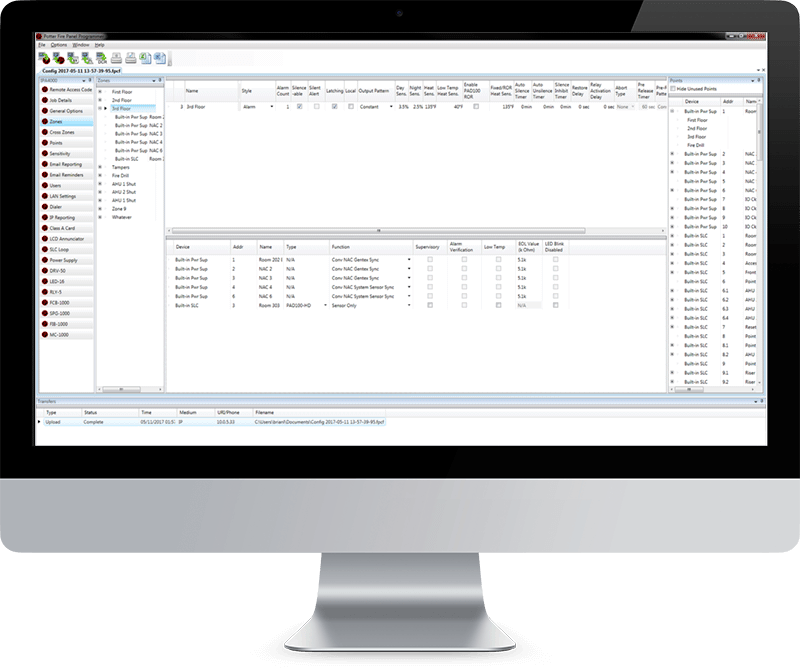

Panel Programmer

Once connected to a network, the panel configuration software allows custom programming and configuration for all points using the network or a stand-alone computer. Fine-tune device behavior characteristics or create mapping zones for a more sophisticated fire protection system. All this is bundled in an easy-to-use drag and drop interface.

Learn MoreIP & Networking

Panel Networking

Potter's peer-to-peer networking solution allows all new and existing IPA Series, AFC Series, and PFC-4064 fire alarm panels to communicate on a dedicated ethernet or fiber network. When networked, users can allow point control between panels, use a single panel for central station reporting for a network, and employ network annunciators for total system control on up to 200 panels.

Learn More

IP Connectivity

With today's ever-expanding means of communication, it's important to be able to incorporate the same technology into your fire control system. We took this technology into account when we designed IP connectivity within our new panels.

By eliminating the cost of phone lines, save big when using your building's existing network infrastructure. Additionally, the speed of IP communication allows for event information to be sent to the central station within seconds. Every Potter IP-enabled fire alarm system has an onboard IP communicator that is listed to communicate with the Sur-Gard III IP receiver.

Learn More

Emails & Reminders

Potter IP-enabled fire alarm systems are email ready. History and Detector Status reports can be sent on demand as either a text or Excel® file for a professional look. The status events of the panel can be immediately emailed allowing users to be proactive in servicing customers.

Reports and the configuration file can be requested from the panel at any time by sending an email directly to the panel. Additionally, enhance your business by creating email reminders for your customers to schedule system tests or even to purchase new batteries.

Learn MoreIPA System Features

Programmable EOLs

NACs and I/Os have programmable EOLs between 2.0k and 27k. This can be achieved manually by installing the resistor and using the panel's LEARN function, or automatically through the programming software.

Dipswitch Programming

Potter Protocol devices are now programmed through easy-to-use dip-switches. This makes it easier than ever to address SLC devices on-site and requires no external hardware.

Multi-Connect

The MC-1000 Multi-Connect Module allows up to 62 client fire panels to communicate with a remote/central station through a single control panel designated as the host. This can eliminate the need for multiple phone lines and monitoring accounts. Each MC-1000 module includes terminal connections for two client panels.

Quadrasync

Our patented Quadrasync technology allows four different brands of strobes to be synced together using a Potter fire alarm control panel or PSN Series power supply. There is no need for the panel and devices to utilize the same protocol, making this technology a great feature for retrofit applications. Quadrasync works with the Potter®/Gentex®, Amseco®, System Sensor®, and Wheelock® protocols.

Designed & Assembled in the USA

Potter prides itself on offering a full line of fire alarm equipment assembled in St. Louis, Missouri and Branford, Connecticut. With engineering teams located in Maple Grove, Minnesota; Moline, Illinois; and Louisville, Kentucky; Potter continues to provide the latest innovations direct from America's heartland.