CorrosionTesting

In recent years, studies have shown that corrosion causes a steady decline in a fire sprinkler system if not properly maintained.

Symptoms of corrosion include pinhole leaks, smelly water, black water and tubercles (mounds on pipe wall).

These symptoms have long been considered normal for fire sprinkler systems. Unfortunately, these "normal" conditions cost the industry millions of dollars annually. There are many other signs of corrosion; however most will generally involve a closer look at the system.

Potter offers several very simple, non-invasive methods in which to test your system and provide answers to 3 very important questions:

Do you have corrosion in your system?

What kind of corrosion do you have?

How should you handle that corrosion?

Corrosion Solutionsfor NFPA 13 & 25

NFPA 25, 2014

14.2.1

An assessment of the internal condition of piping shall be conducted…

…on a frequency determined by 14.2.1.1 or 14.2.1.2 for the purpose of inspecting for the presence of foreign organic and inorganic material.

It also allows for alternative examination methods such as A.14.2.1 "A laboratory analysis of water samples obtained from the fire protection system, combined with collecting and inspecting solid material from fire protection system water discharged from a main drain, and an inspector's test connection, can provide an indication of the presence of corrosion, MIC, and/or foreign materials."

Potter's Solution:

5 Year Deposit / Sludge Test Kit

NFPA 25, 2014

14.2.1.3

Tubercules or slime, if found, shall be tested…

…for indications of microbiologically influenced corrosion (MIC).

Potter's Solution:

5 Year Deposit / Sludge Test Kit

NFPA 13, 2016

24.1.5.1

Water supplies and environmental conditions shall be evaluated…

for the existence of microbes and conditions that contribute to Microbiologically Influenced Corrosion (MIC).

Potter's Solution:

Corrosion TestingOnline Store

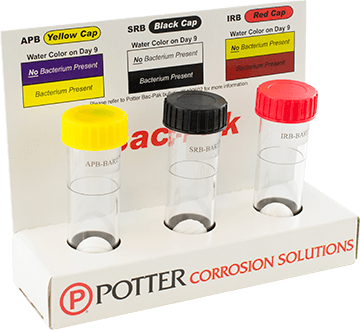

BAC-PAK

Bacterium Test Kit

The BAC-PAK is a do-it-yourself test kit designed to allow field testing of wet pipe sprinkler systems and/or water supplies for MIC causing bacterium. The kit allows field testing for; Iron related bacterium (iron-pipe oxidizing and reducing bacterium); Sulfate Reducing Bacterium (causes pit corrosion) and Acid Producing Bacterium (causes pit corrosion). The testing takes just a few minutes. The results will appear over a period of up to 9 days to allow for bacteria culture growth.

View more info about the BAC-PAK$215

WTK

Water Test Kit

This kit is designed to conform to the requirements of NFPA 13, 2013, 24.1.5.1 requiring:

Water supplies and environmental conditions shall be evaluated for the existence of microbes and conditions that contribute to microbiologically influenced corrosion (MIC).

Five groups of bacteria will be Tested: Heterotrophic Bacterium which determines if the majority of bacterium are anaerobic (without air) or aerobic (with air) in nature; Slime Forming Bacterium (aids in tubercle formation); Iron Related Bacterium (iron-pipe oxidizing and reducing bacterium); Sulfate Reducing Bacterium (causes pit corrosion) and Acid Producing Bacterium (causes pit corrosion).

A full written report will be provided approximately 15 business days after testing is started.

View more info about the WTK$425

Pipe Failure Corrosion Analysis

This analysis is available for identification of the corrosion/failure mechanism, i.e. pitting corrosion, stress corrosion cracking, microbiologically influenced corrosion, galvanic corrosion, etc. of failed sprinkler pipe. The analysis involves removing a section of the failed pipe from the fire sprinkler system and sending to a certified third party lab for testing. Material flaw/quality evaluations will be made to determine potentially related factors to the failure condition. This will include metallographic examination for microstructural flaws or abnormalities.

The methods used in the failure / corrosion analysis will typically include visual examination, examination by optical microscopy, examination by scanning electron microscopy (SEM), metallographic examinations (cross-sectional examination of material microstructure), energy dispersive spectroscopy (EDS) of corrosion products/residues, microbiological activity studies, hardness survey and chemical analysis. A formal report, with photographic documentation will be generated upon completion approximately 15 business days after the test is started.

View more info about the Pipe Failure Corrosion Analysis$2,950

Pipe Sample Test

This kit is designed to conform to the requirements of NFPA 25, 2011, 14.2.1.3 requiring:

Tubercules or slime, if found, shall be tested for indications of microbiologically influenced corrosion (MIC)

The test involves removing some of the slime, deposit, scale, tubercules, mounds, etc. from the pipe section at Potter for microbiologically influenced corrosion (MIC) analysis.

Five groups of bacteria will be tested: Heterotrophic Bacterium which determines if the majority of bacterium are anaerobic (without air) or aerobic (with air) in nature; Slime Forming Bacterium (aids in tubercle formation); Iron Related Bacterium (iron-pipe oxidizing and reducing bacterium); Sulfate Reducing Bacterium (causes pit corrosion) and Acid Producing Bacterium (causes pit corrosion).

A full written report will be provided approximately 15 business days after testing is started.

View more info about the Pipe Sample Test$625